25.1~32.5m³/min Two Stage Screw Air Compressor 180KW Air Cooling or

Water cooling

| Air intake status | ≤Ambient temperature intake pressure 1.013bar(A) | Voltage(V)

Frequency(Hz) | 380V50Hz |

| Start-ups | Y-△ | Noise dB(A) | 72±5dB |

| Oil Content | 1~3ppm | Outlet Air Temperature | ambient temperature+8℃

|

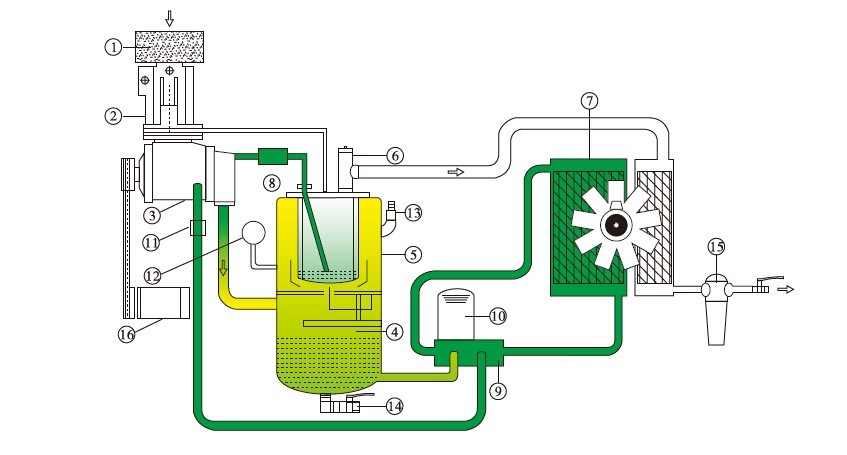

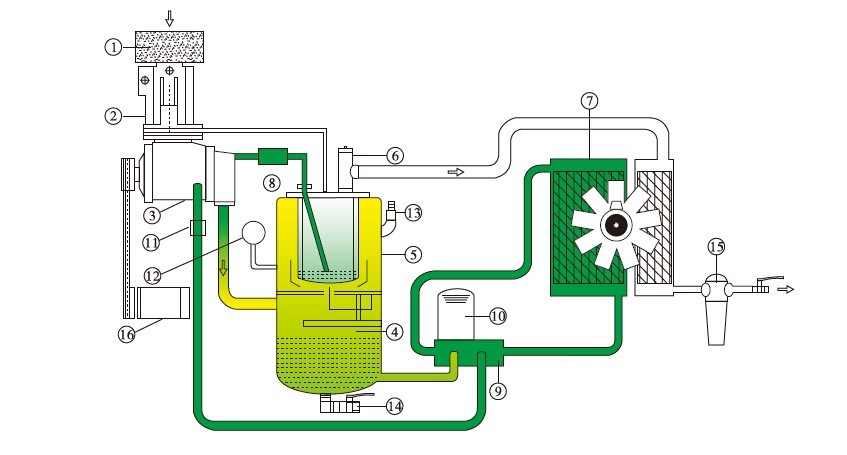

⊙ Schematics

| 1. Air Filter | 9. Oil Temperature Control Valve |

| 2. Air-in Easing Value | 10. Oil Filter |

| 3. Principal Screw Machine | 11. One-way Shut-off Valve |

| 4. Oil Air Separator | 12. Pressure Gage |

| 5. Oil Air Separating Filter Core | 13. Safety Valve |

| 6. Minimum Pressure Valve | 14. Vent Valve |

| 7. Radiator with Aluminum Alloy Fans | 15. Compressed Air Dry Separator |

| 8. Return Check Valve | 16. Motor |

⊙ Twin-screw air compressor introduced mainframe

Spray

All are screw-type compressor with a modem environmental-protection

paint. Its surface machining so many years after the use of

castings can effectively avoid corrosion.

Shell

The modem word processing centers under the control of the

technical specifications for testing. ’The most advanced machinery

and the use of modem technology and constant monitoring. It applied

to all processing operations. For us on the Company’s compressor

quality certification of the commitments made by providing good

protection.

Shaft sealing device

Equipped with dual wheels metal framework amine fluoride rubber

ring to withstand certain pressures. Formation of the shaft seal

can be lubricating device. Bush axis of the company’s exclusive use

my special processing technology. A perfect sealing performance and

long life.

Rotor

Each screw compressor is the heart of the compressor mainframe.

From the latest CNC machine operators of multi-level screw fully

automated manufacturing process and materials used by the higher

minimum guarantee its tolerance. Reliability stronger. Ground

processing and computer control of the multi-step rotor combine.

100% of the rotor to ensure the accuracy of profile.

Bearing

To ensure the speed and load bearing capacity. Using screw

compressor bearing capacity of a very high-quality bearings.

Guaranteed longer bearing life.

⊙ why choose us

Longer service life of the master machine

The rotor uses asymmetrical line running at a low speed with the

support of the ball bearings and roller bearings as a result. The

damage and the cost are lowered and the service life is extended.

Some force is counteracted by the axial force generated by the

bevel gear. So the load on the bearings of the master machine is

lowered.

Permanent alignment of the electromotor and the master machine

Different from the strap compressor, the SRC series compressor can

integrate the electromotor with flange, shaft coupling box-gear

box. and the master machine into one in such way the master machine

and the electrometer are aligned forever in the transpiration. The

SRC series compressors equipped with effective and fully sealed

air-cooling electromotor.

⊙ Type air compressor pause

| Specifacation | Cooling Style | Air Capacity

(m³/min) | Discharge Pressure

(bar) | Motor Power

(kw) | Speed

(r/min) | Voltage(V)

Frequency(Hz) | Cooling Air Capacity

(m3/min) | Joint pipe Size

(inch) | Total Weight

(kg) | Dimension(L*W*H)

(mm) |

| SRC-7.5SA | Air cooling | 0.85 | 7 | 5.5 | 2980 | 380V50Hz | 80 | 1/2″ | 230 | 850*735*990 |

| 0.8 | 8 |

| 0.6 | 10 |

| 0.4 | 13 |

| SRC-10SA | Air cooling | 1.1 | 7 | 7.5 | 2980 | 380V50Hz | 80 | 1/2″ | 410 | 850*735*990 |

| 1 | 8 |

| 0.8 | 10 |

| 0.6 | 13 |

| SRC-15SA | Air cooling | 1.7 | 7 | 11 | 2980 | 380V50Hz | 80 | 1/2″ | 475 | 1100*750*1150 |

| 1.6 | 8 |

| 1.4 | 10 |

| 1.2 | 13 |

| SRC-20SA | Air cooling | 2.4 | 7 | 15 | 2980 | 380V50Hz | 100 | 1″ | 560 | 1350*850*1150 |

| 2.2 | 8 |

| 2.1 | 10 |

| 1.7 | 13 |

| SRC-25SA | Air cooling | 3.1 | 7 | 18.5 | 2980 | 380V50Hz | 145 | 1″ | 580 | 1350*850*1150 |

| 2.9 | 8 |

| 2.7 | 10 |

| 2.2 | 13 |

| SRC-30SA | Air cooling | 3.8 | 7 | 22 | 2980 | 380V50Hz | 145 | 1″ | 640 | 1350*850*1150 |

| 3.5 | 8 |

| 3.2 | 10 |

| 2.7 | 13 |

| SRC-40SA | Air cooling | 5.2 | 7 | 30 | 2980 | 380V50Hz | 255 | 1″ | 900 | 1350*850*1150 |

| 5 | 8 |

| 4.3 | 10 |

| 3.7 | 13 |

| SRC-50SA | Air cooling | 6.4 | 7 | 37 | 2980 | 380V50Hz | 255 | 1½″ | 980 | 1550*950*1450 |

| 5.9 | 8 |

| 5.5 | 10 |

| 4.8 | 13 |

| SRC-60SA | Air cooling | 8 | 7 | 45 | 2980 | 380V50Hz | 255 | 1½″ | 1050 | 1550*950*1450 |

| 7.7 | 8 |

| 7 | 10 |

| 5.8 | 13 |

| SRC-75SA | Air cooling | 10.5 | 7 | 55 | 2980 | 380V50Hz | 268 | 2″ | 1250 | 1900*1240*1700 |

| 9.8 | 8 |

| 8.7 | 10 |

| 7.5 | 13 |

| SRC-90SA | Air cooling | 11.7 | 7 | 65 | 2980 | 380V50Hz | 268 | 2″ | 1530 | 1900*1240*1700 |

| 11.3 | 8 |

| 9.5 | 10 |

| 8.4 | 13 |

| Specifacation | Cooling Style | Air Capacity

(m³/min) | Discharge Pressure

(bar) | Motor Power

(kw) | Oil Content | Cooling Air Capacity

(m3/min) | Cooling Water Capacity

(m3/h) | Joint pipe Size

(inch) | Total Weight

(kg) | Dimension

(L*W*H)

(mm) |

| SRC-100SA/SW | Air cooling

Water Cooling | 13.6 | 7 | 75 | 1~3ppm | 400 | 5 | 2″ | 1850 | 1900*1240*1700 |

| 13 | 8 |

| 11.6 | 10 |

| 10 | 13 |

| SRC-120SA/SW | Air cooling

Water Cooling | 16 | 7 | 90 | 1~3ppm | 400 | 6 | DN80 | 2100 | 2640*1540*1880 |

| 15.5 | 8 |

| 14 | 10 |

| 11.5 | 13 |

| SRC-150SA/SW | Air cooling

Water Cooling | 20.8 | 7 | 110 | 1~3ppm | 600 | 8 | DN80 | 2580 | 2640*1540*1880 |

| 19.5 | 8 |

| 17.5 | 10 |

| 15.5 | 13 |

| SRC-175SA/SW | Air cooling

Water Cooling | 24 | 7 | 132 | 1~3ppm | 630 | 9 | DN80 | 2700 | 2640*1500*1880 |

| 23 | 8 |

| 20 | 10 |

| 18 | 13 |

| SRC-200SA/SW | Air cooling

Water Cooling | 27.7 | 7 | 160 | 1~3ppm | 850 | 10 | DN80 | 3200 | 2640*1540*1880 |

| 26.5 | 8 |

| 22.5 | 10 |

| 20.1 | 13 |

| SRC-250SA/SW | Air cooling

Water Cooling | 32.5 | 7 | 180 | 1~3ppm | 850 | 12 | DN100 | 3700 | 3150*1830*1900 |

◆Type selection of working pressure (exhaust pressure)

When the user is ready to purchase an air compressor, the first

thing is to determine the working pressure needed at the gas end,

plus a margin of 1-2 bars, and then select the pressure of the air

compressor. (This margin is to consider the pressure loss from the

installation site of the air compressor to the actual pipeline of

the gas end, and to consider the pressure margin between 1-2 bars

according to the length of the distance). Of course, the size of

pipeline diameter and the number of turning points are also factors

affecting pressure loss, the larger the pipeline diameter and the

fewer turning points, the smaller the pressure loss; conversely,

the greater the pressure loss.

Therefore, when the distance between the air compressor and the

gas-end pipeline is too far, the diameter of the main pipeline

should be enlarged appropriately. If the environmental conditions

meet the installation requirements of the air compressor and the

working conditions permit, it can be installed near the gas

terminal.

◆Selection of volume flow rate

①When choosing the volume flow rate of air compressor, we should

first know the volume flow rate of all the gas-using equipment and

multiply the total flow rate by 1.2 (that is, to enlarge the 20%

margin).

②the new project can be selected according to the flow rate

provided by the design institute.

③to understand the volume and flow parameters of the gas

consumption equipment for the gas supplier.

④Air compressor station transformation can refer to the original

parameter value and the actual gas consumption.

Appropriate type selection is beneficial to users and air

compressor equipment. Too much waste of type selection and too

small type selection may cause the air compressor to be in a

long-term loading state or insufficient gas consumption or pressure

can’t be beaten up.

◆The relationship between the three power, work pressure and volume

flow rate

When the power is unchanged, the volume flow rate and working

pressure will change correspondingly when the rotational speed

changes. For example, a 22KW air compressor is manufactured with a

working pressure of 7bar, and the rotational speed is calculated

according to the technical curve of the main engine of the air

compressor. The exhaust volume is 3.8 m3/min. When the working

pressure is 8bar, the rotational speed must be determined. It must

be reduced (otherwise the drive motor will be overloaded), at this

time, the exhaust volume is 3.6 m3/min; because the speed is

reduced, the exhaust is reduced accordingly, and so on.

The selection of power is based on the condition that the working

pressure and volume flow are satisfied, and the power supply

capacity can meet the use power of the matched driving motor.

Therefore, the selection of air compressor steps are: first

determine the working pressure, then determine the corresponding

volume flow, and finally the power supply capacity.

◆Consider the combination of gas fields and conditions.

If the use of air space is narrow (marine, automotive), it should

be vertical; if there is a long-distance change in the use of air

(more than 500 meters), it should consider mobile; if the use of

electricity can’t be used, it should choose diesel engine driving;

if there is no running water in the use of occasions, it must

choose air-cooled.

Users often have a wrong idea about air-cooled and water-cooled

cooling modes. They think that water-cooled is good. Air-cooled

modes account for more than 90% of small air compressors at home

and abroad. This is because air-cooled is simple in design and no

water source is needed in use.

There are four fatal shortcomings of water-cooled air compressor:

it must have complete upper and lower water system with large

investment; water-cooled cooler has short life; it is easy to

freeze the cylinder in winter in the north; it will waste a lot of

water in normal operation.

◆Consider the quality of compressed air.

Generally, compressed air produced by air compressors contains a

certain amount of lubricating oil and a certain amount of water. In

some cases, oil and water are forbidden. At this time, attention

should be paid not only to the selection of air compressors, but

also to the addition of ancillary devices when necessary.

The solution is to select a non-lubricated air compressor. The air

compressor cylinder is basically oil-free, and its piston rings and

fillers are generally polytetrafluoroethylene. But this machine

also has shortcomings, poor lubrication, high failure rate; PTFE is

also a harmful substance, food, pharmaceutical industry can’t use;

no lubrication air compressor can only achieve gas transmission

without oil, can’t do without water. The second and commonly used

method is to add the air compressor (either) to the first or second

stage purification device or dryer. This device can make the air of

air compressor contain neither oil nor water, and make the oil and

water content in compressed air less than 5 ppm, which can meet the

technological requirements.

◆We should consider the safety of air compressor operation.

Air compressor is a kind of machine working under pressure, which

is accompanied by temperature rise and pressure, and its safety

should be put in the first place. The state implements a

standardized "two certificates" system for the production of air

compressors, i.e. air compressor production license and pressure

vessel production license (gas storage tank). Therefore, when

selecting air compressor products, we must strictly examine the

"two certificates". Usually the quality assurance system of

certified manufacturer is perfect, there will be no major quality

problems, even if there are some problems, the manufacturer will be

responsible for three packages.

◆Description:

♦ Fully seal & double screw, dual shockproof, smooth operation, can

be installed anywhere.

♦ With a exquistie shape and compact structure and cover a small

area.

♦ Large displacement, stable pressure and high efficiency.

♦ Low exhause temperature (only 7 °C~10°C higher than the ambient

temperature)

♦ Safe, liable, smooth operation, little noise and long maintenance

cycle and using life.

♦ The intelligent control system completely satisfy the continuous

cooperation without man work.

♦ Many screw air compressors operate together and start or shut

down automatically

according to the air amount, and no man-work is needed.

♦ It is more energy saving for a single compressor can adjust air

demand automatically according to the users' air amount(frequency

conversion type).